Fab Labs and Hackerspaces: Neighborhood Engines of Innovation

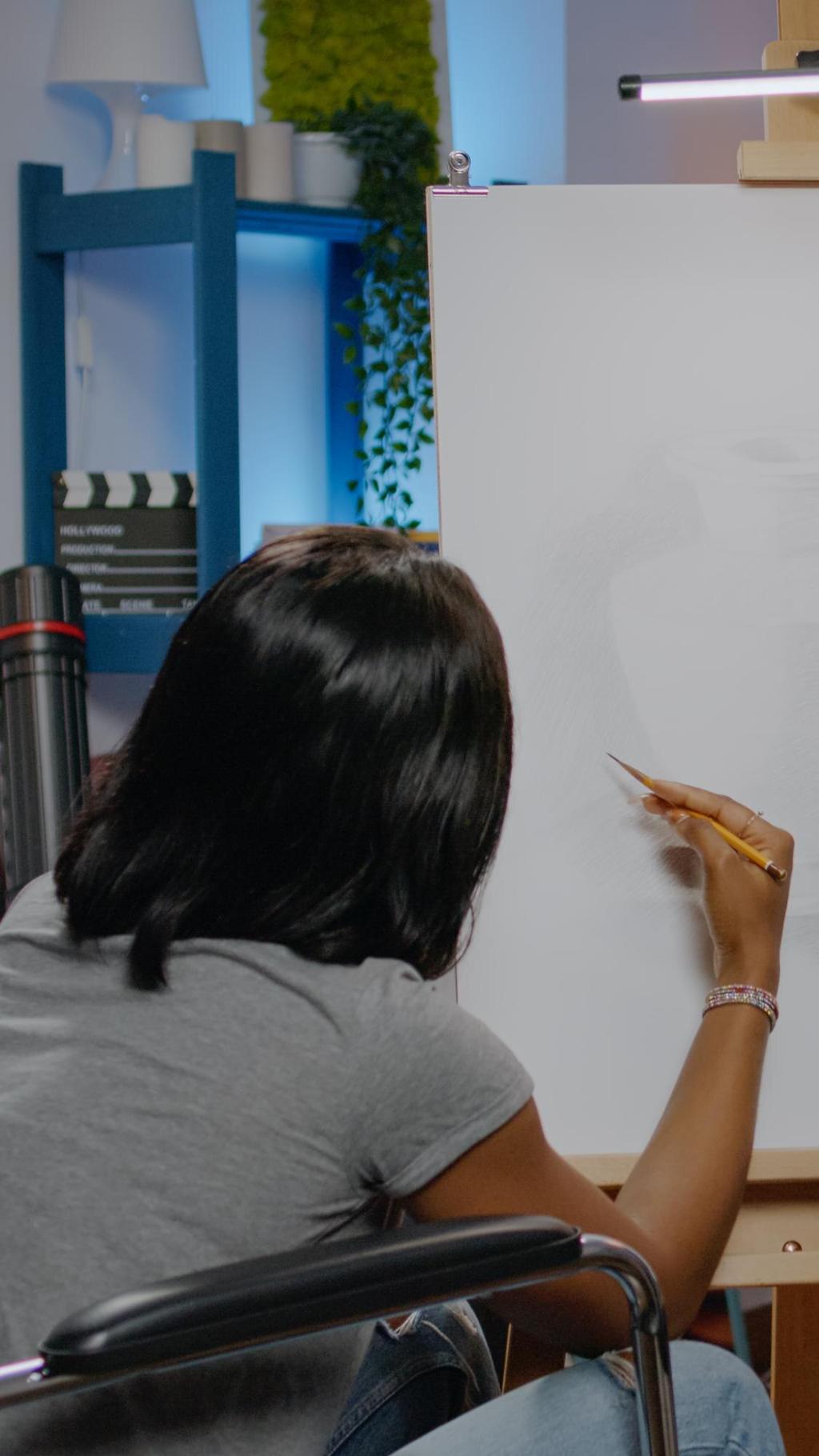

Access to tools, respect for safety, and a culture of teaching hitched together to amplify creativity. Machines weren’t trophies; they were invitations to collaborate, prototype bravely, and document every messy, magnificent iteration.

Fab Labs and Hackerspaces: Neighborhood Engines of Innovation

Weekly build nights, parts bins, and whiteboards filled with doodled belt paths fostered trust. You could arrive with questions and leave with a plan, a mentor, and sometimes a pocketful of PLA test scraps.