The Maker Movement Reshapes the Narrative

Adrian Bowyer’s RepRap project sparked a movement in 2005: a printer designed to replicate many of its own parts. Kits, wikis, and late-night soldering sessions followed. Did RepRap catalyze your journey? Tell us your first successful print and the lesson it taught.

The Maker Movement Reshapes the Narrative

When critical FDM patents expired around 2009, desktop printers flourished. Prices dropped, startups multiplied, and tutorials bloomed. If you rode that wave—MakerBot, Prusa, or DIY—comment with your favorite failure that eventually led to a breakthrough.

The Maker Movement Reshapes the Narrative

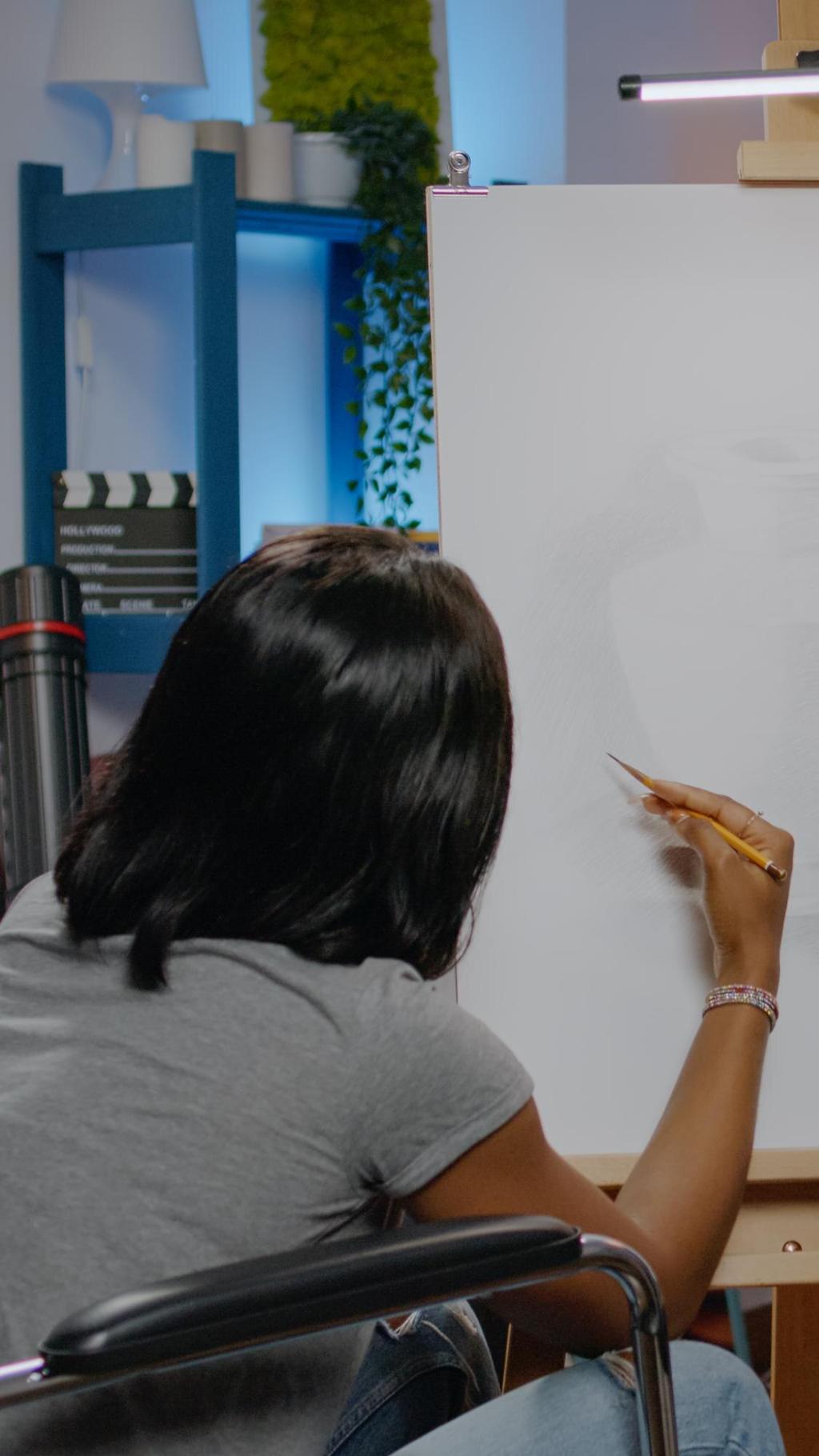

Design sharing platforms transformed isolated tinkering into global collaboration. Open STL libraries, forums, and video channels accelerated learning and quality. Which community saved your project with a clever fix? Join our newsletter and swap notes with fellow builders.

The Maker Movement Reshapes the Narrative

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.